Heat Pump Compressor Cost Estimator

Estimate Your Cost

Enter your system details to get an accurate replacement cost estimate.

Estimated Cost Breakdown

Estimated Savings Comparison

Replacing your system instead of just the compressor could save you money in the long term if your unit is older than 12 years and has low efficiency.

A new system could save you up to $0.00 annually on energy bills over the next 10 years.

When your heat pump stops blowing warm air in winter or cool air in summer, the culprit is often the compressor. Knowing heat pump compressor cost before you call a tech can save you from surprise bills and help you decide whether to repair or replace.

What Exactly Is a Heat Pump Compressor?

Heat pump compressor is a mechanical device that pressurizes refrigerant, turning low‑pressure gas into high‑pressure gas so the system can move heat from one place to another. This component is the heart of any air‑source or ground‑source heat pump. Without a functioning compressor, the refrigerant never gains the energy needed to transfer heat, meaning the whole system is useless.

Typical Price Ranges in 2025

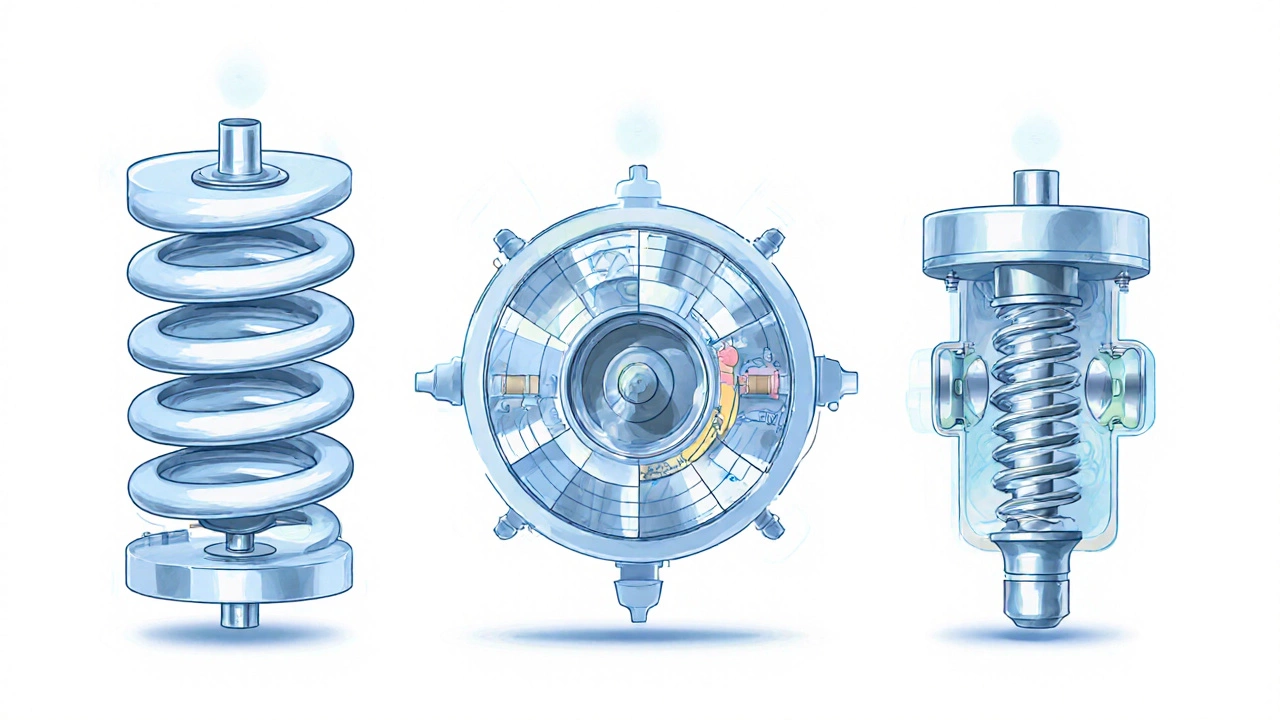

Compressors come in three main designs, and each carries its own price tag. Below is a quick snapshot of what you’ll see on a typical wholesale or retailer site in October 2025:

| Compressor Type | Typical Unit Cost (USD) | Best For | Efficiency Rating (COP) |

|---|---|---|---|

| Scroll | $800 - $1,200 | Residential 2‑3 ton units | 3.5 - 4.2 |

| Rotary | $600 - $900 | Smaller 1‑2 ton units | 3.2 - 3.8 |

| Screw | $1,400 - $2,200 | Large commercial or multi‑zone systems | 4.0 - 5.0 |

These numbers cover the part alone. Labor, disposal, and any required ancillary parts can push the final bill higher.

Breakdown of the Total Replacement Bill

When you add up everything, most homeowners see a total ranging from $1,300 to $3,000. Here’s where the money goes:

- Compressor Unit: $600‑$2,200 depending on type and capacity.

- Labor: HVAC technicians typically charge $85‑$130 per hour. A full replacement takes 3‑5 hours, so labor runs $250‑$650.

- Copper Tubing & Fittings: If the old copper is corroded, you’ll need new sections - usually $50‑$150.

- Refrigerant Recharge: Modern heat pumps use R‑410A or newer low‑GWP refrigerants, costing $100‑$180 per pound. A typical 2‑ton system needs 2‑3 lbs.

- Thermostat Re‑calibration: After a compressor swap, the control board often needs a reset, which is a $30‑$70 service fee.

- Warranty Extension: Manufacturer warranties are 5‑years on parts; buying an extended warranty adds $100‑$250.

So a mid‑range scroll compressor replacement on a 3‑ton unit usually lands around $1,800‑$2,200 total.

Factors That Push the Cost Up or Down

Not every job is created equal. Below are the biggest knobs you can turn to influence the final price:

- System Size: Larger tons need bigger compressors, which are more expensive.

- Compressor Type: Screw units dominate commercial pricing; scroll units are the sweet spot for most homes.

- Brand Preference: Premium brands like Carrier, Trane, and Mitsubishi carry a markup of 10‑20% over generic OEM parts.

- Installation Complexity: If the existing copper is hard‑to‑reach behind walls or in a crawlspace, labor climbs.

- Geographic Location: Labor rates in the Northeast tend to be higher than in the Midwest.

- Seasonal Demand: Summer heat‑wave weeks can see a 15% surge in labor rates.

How to Diagnose a Bad Compressor Before You Pay

Before you hand over a check, make sure the compressor truly needs swapping. Here are three low‑cost checks you can do yourself:

- Listen for Humming: Turn the thermostat to heat or cool. A healthy compressor produces a steady, low‑pitch hum. A rattling or grinding noise often means internal wear.

- Check the Outdoor Unit: If the fan spins but the unit never gets warm or cold, the compressor may be dead.

- Measure Refrigerant Pressure: A DIY gauge set (available for $30‑$50) can tell you if the high‑side pressure is abnormally low, which points to a compressor problem.

If any of these signs appear, it’s time to call a certified HVAC technician. They’ll run a professional voltage test and verify that the motor windings haven’t shorted.

Step‑by‑Step Guide to a Compressor Replacement

Even if you hire a pro, knowing the workflow helps you stay on budget and avoid surprise fees.

- Shutdown & Power Off: Turn off the breaker to the heat pump and lock out the circuit.

- Recover Existing Refrigerant: A certified technician uses recovery equipment to capture the refrigerant safely - required by EPA regulations.

- Disconnect Copper Lines: Cut the suction and discharge lines, cap them with proper fittings, and label each side.

- Remove the Old Compressor: Unbolt the unit from the crankcase, pull it out, and inspect for oil leaks.

- Install the New Compressor: Align the mounting holes, torque bolts to the manufacturer’s specs (usually 30‑35 Nm), and bolt in the new unit.

- Replace Seals & O‑Rings: Fresh seals prevent future leaks and are a small $10‑$20 expense.

- Reconnect Copper Lines: Solder new copper tubing if the old pieces are corroded, then evacuate the system to remove moisture.

- Recharge Refrigerant: Add the correct charge according to the manufacturer’s pressure‑temperature chart.

- Test Run: Cycle the thermostat through heating and cooling, check for steady pressures, and verify temperature differentials.

- Finalize & Document: Write down the new serial number, refrigerant type, and warranty details for future reference.

Most homeowners can watch the process, but never attempt the refrigerant recovery or high‑pressure work yourself - it’s illegal without a certified technician.

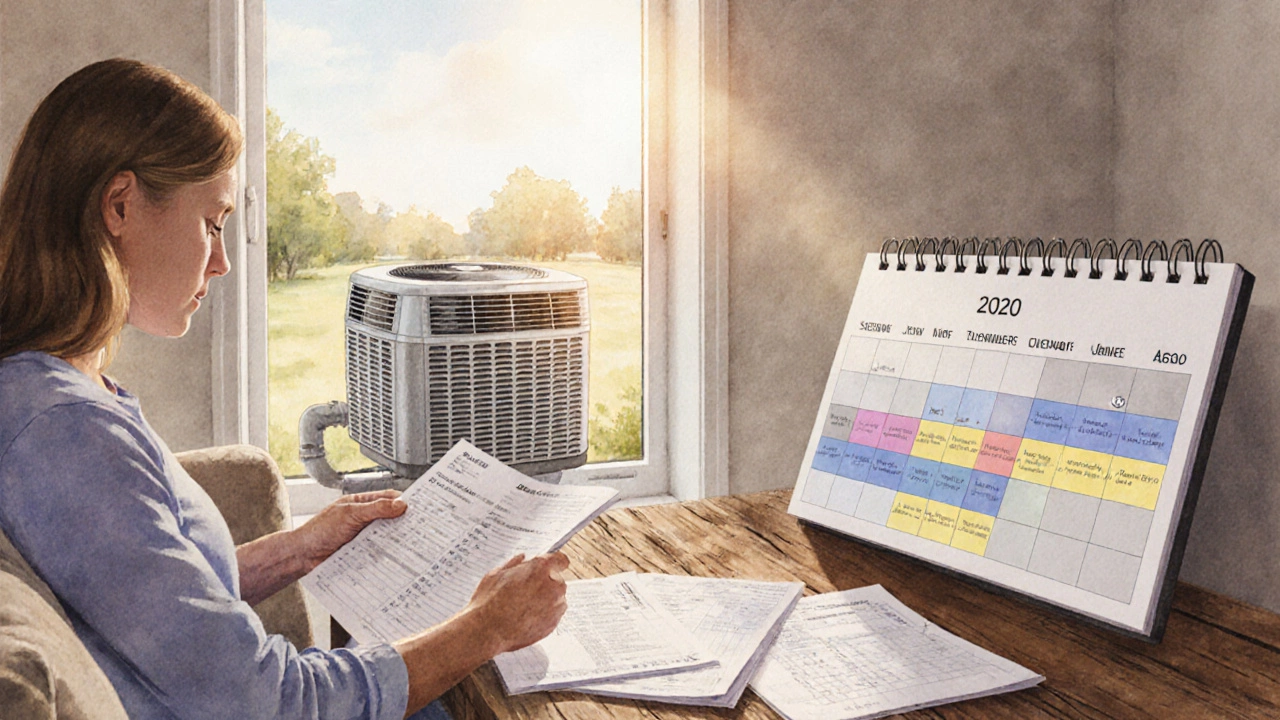

When It Makes Sense to Replace the Entire Heat Pump

If your unit is more than 12‑15 years old, the compressor cost might be a fraction of a whole‑system replacement. Consider the following:

- Age & Warranty: Older units are out of warranty and may have other failing components like the indoor coil.

- Energy Efficiency: New 2024‑2025 heat pumps boast SEER 20+ and COP 4.5+, cutting your electricity bill by 30‑40%.

- Rebate Opportunities: Many utilities offer $500‑$1,500 rebates for installing high‑efficiency systems.

In these cases, a full replacement (typically $5,000‑$9,000 installed) could pay for itself in a few years.

Tips to Keep Replacement Costs in Check

Here are five pro tricks that keep the price tag lean:

- Get Three Quotes: Competition drives down labor rates. Ask each contractor to break down parts, labor, and taxes.

- Check for Manufacturer Specials: Brands often run “free labor” promos on compressors when you buy the part directly.

- Reuse Good Copper: If the existing tubing is in good shape, a smart tech can salvage it, saving $50‑$120.

- Schedule Off‑Season: Booking in late fall or early spring avoids peak‑hour surcharges.

- Ask About Warranty Transfer: Some OEM warranties are transferable to the homeowner, adding value.

Frequently Asked Questions

How long does a heat pump compressor typically last?

Most compressors last 10‑15 years if the system is serviced regularly. Poor refrigerant charge or high‑temperature operation can shave years off the life.

Can I replace the compressor myself?

Legally no - handling refrigerant requires EPA certification. Even the mechanical removal is tricky and can void your warranty if done incorrectly.

What’s the difference between scroll and rotary compressors?

Scroll compressors use two interleaved spirals, delivering smoother operation and higher efficiency. Rotary units have a single rotating shaft, making them cheaper but slightly less efficient.

Do I need a new thermostat after a compressor swap?

Usually not. The thermostat just sends a signal; however, a calibration check is recommended to ensure accurate temperature readings.

Are there rebates for high‑efficiency compressors?

Many local utilities offer rebates when you install a compressor with a COP of 4.0 or higher. Check your utility’s website for specific program details and filing deadlines.

Armed with these numbers and steps, you can walk into a service call with confidence, ask the right questions, and avoid getting stuck with an unexpected bill. Whether you end up swapping just the compressor or upgrading the whole heat pump, knowing the cost structure empowers you to make the smartest choice for comfort and your wallet.